Planet

Planet

Energy and Emissions

Energy Efficiency

Energy expenses represent a significant operating cost. Reducing energy use in our operations, which in turn reduces our greenhouse gas (GHG) emissions, is the right thing to do for the planet and helps us be more cost efficient. We have been working to reduce our energy use and GHG emissions, primarily by increasing the energy efficiency of our operations and by increasing the use of renewable energy. Our teams track the efficiency of each of our facilities, evaluating opportunities to improve or replace equipment with energy efficiency in mind.

Greenhouse Gas Emissions

We measure and report Scope 1, Scope 2 (location-based) and certain Scope 3 GHG emissions. We continue to monitor and expand the measurement and reporting of our complete Scope 3 footprint.

August 2024 Update: Following a comprehensive, multi-year analysis, we are proud to announce our goals to decrease absolute Scope 1 and 2 emissions by 42% and absolute Scope 3 emissions by 25% by the end of 2030 from a 2022 base year. These targets align with current climate science and the Paris Agreement’s goals.

Building on the progress we have made with changes reducing the emissions of our company’s operating footprint, we intend to leverage innovative energy efficiency projects; increase our use and support of renewable energy; and partner with large suppliers to reduce their contributions to our Scope 3 emissions.

For detailed reporting on our GHG emissions inventory, please consult our latest CDP Climate Questionnaire.

Sustainable Forestry

Forests provide social and economic value to the communities in which we live and work. They offer sources of income for landowners, jobs for local residents, spaces for recreation and habitats for many species.

These spaces help to mitigate the effects of climate change by providing long-term capture and sequestration of CO2. Our success as a company depends on a sustainable supply of wood fiber, and we are committed to promoting and enabling responsible forest management.

Our Forestry Policies

We are committed to Net Zero Deforestation across our wood basin through our fiber procurement practices. This means holding ourselves and our suppliers accountable. In 2022, we implemented our Sustainable Forestry Policy to promote sustainable forestry and development.

Responsible Fiber Procurement

To support sustainable forestry practices and customers’ requests, we look to procure responsibly sourced fiber. As of December 31, 2023, 100% of our procured virgin fiber met at least one of the three internationally recognized fiber sourcing standards. Additionally, all of our applicable facilities in North America have been certified to ensure we follow strict chain of custody standards to track forest fiber content (forest content, certified sourcing and recycled content) through production and manufacturing of the end product.

Download Our Brief on Forest Certification

Water Management

The majority of our water use is classified as nonconsumptive — used in our facility, treated and returned back to the environment. We monitor water used and discharged daily at various stages throughout our manufacturing processes to assess the efficiency of our operations and the efficacy of our treatment systems.

In addition to our daily water management activities, we conduct an annual analysis using the Aqueduct Water Risk Atlas from the World Resources Institute to assess the water stress level of the regions where our plants are located. Assessments help us evolve our water management strategy, prioritizing facilities based on water usage and risk area. According to our 2022 assessment, while 12% of our facilities are located in medium-high to high water risk areas, 99% of our water intake occurs in low or low-medium water risk areas.

Reducing Waste

We have undertaken a multi-year, company-wide analysis of waste and recycling at all of our facilities. This has included surveys with facility managers, classification of equipment and material types and reviews of multiple vendors’ data. The analysis has identified many opportunities for improvement, which will help inform the development of a waste and recycling strategy, striving for zero waste in all operations in the future.

Beyond our own facilities, we encourage our customers’ efforts to reduce waste. We have published a complimentary Zero Waste Implementation Guide to help them begin their journey to zero waste. The interactive guide helps our customers to document waste data and progress, and detailed tools are included to help them perform a waste audit, improve waste and materials management and implement a new bin and signage system.

Fostering Environmental Stewardship

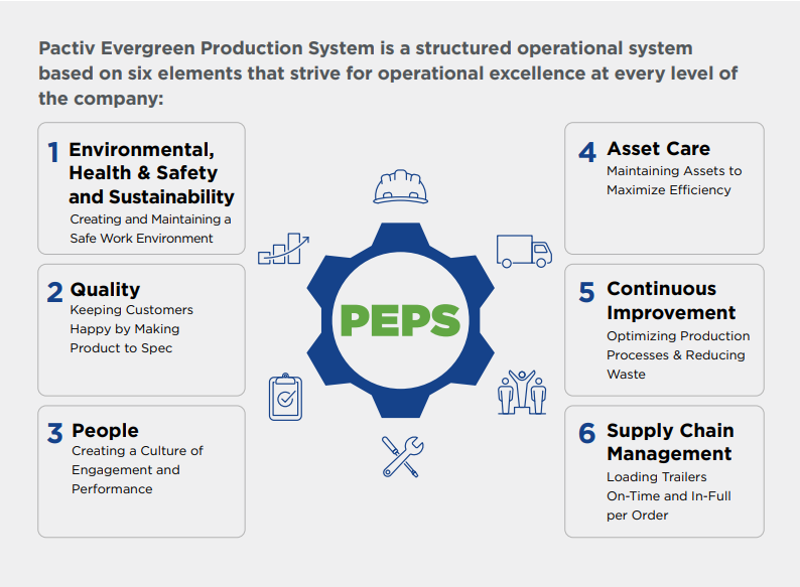

In seeking a way to ensure consistent performance of our operations from one location to the next, we developed the Pactiv Evergreen Production System (PEPS) in 2022. PEPS serves as the road map to success at each facility. PEPS drives accountability by incentivizing adherence to a specific performance level and promotes continuous improvement and sharing best practices across locations.

Sustainability is embedded in PEPS’s first element and is implemented by a network of over 140 PEPS Sustainability Champions throughout all our facilities, dedicated to supporting our sustainability initiatives in the field.